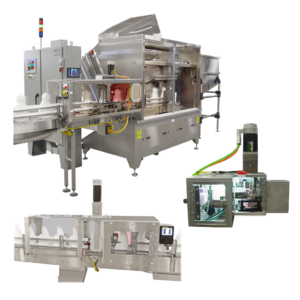

Nalbach Engineering’s Inline 180 degree bottle orientor quickly, simply and inexpensively orients plastic bottles into a common direction.

The NECO-ORIENTER Inline bottle orientor is a servo driven system designed to turn plastic non-round bottles into a common direction. Bottles are accepted from a single lane source and, based upon a Vision sensor’s output allowed to pass if they are properly oriented, or spun 180 degrees if they are not properly oriented.

These orienters are available as stand-alone systems or fully integrated with our line of plastic bottle unscramblers, providing a complete single source solution for bottle unscrambling and orienting applications.

Product Benefits

- Fast. Runs speeds to 300 bpm.

- Simple. The servo motor is the only moving component in the system.

- Inexpensive. Simplicity means lower cost, lower maintenance and higher reliability.

- Easy Access. Hinged top provides easy access to all components and conveyor area.

- Servo Driven. Direct coupled servo drive design reduces part count while providing speed and accuracy.

- Vision system detects the smallest details for fast, easy, and accurate system setup.

- LEXAN enclosure provides complete visibility of the system’s operation. Small and compact for easy integration.

- Easily fits into existing layouts without requiring a large section of dedicated conveyor.

- Fast changeovers. Easy change “turning forks” quickly and accurately change from one bottle format to another.